HOW TO TEST ICs CHIPS by Multimeter

They are 2 basic method to check ICs.

1) On circuit testing . If you have oscilloscope and know how circuit is working such as input , output ,condition to on and off , type of signal ; then you can consider it as block diagram and section to test.

At the ICs you will check input voltage is present or not , output occur after the input switch on/off or not. Including Vcc of ICs should be value as its rated voltage.

2. VCC and ground terminal resistance checking. As inside the ICs there is some circuit , it need voltage to supply and the circuit inside must not " short circuit " and " open circuit" these is the basic condition for good ICs , we will apply this to check ICs and describe below.

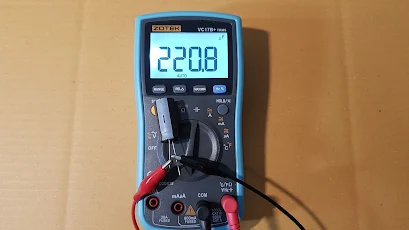

Take ICs part number that marked on its body to find pinning function on datasheet , find where is VCC and ground pin locate. Some ICs has many VCC and ground pin , you to check all VCC pinning and it must be good condition for all VCC. I will use ICs part number HD74LS00P for example testing. Set multimeter to resistor test function then connect as shown on photo , measure , and read resistance value.

HD74LS00P pining arrangement ( different ICs part number has different VCC pin allocation )

The notch and circle on ICs mean pin no. 1 start from that point.

| Pin no. 1 start at the dot and notch. |

VCC and GND testing , The first measurement and test leads connection

|

| The first measured resistance value is high ( for good ICs) |

|

| VCC and GND testing , the second measurement and test leads connection. |

The second measured resistance value is lower compare to the first. ( for good ICs)

2.1

Good ICs .... measured resistance value of VCC and ground testing , the first measurement and second measurement , the first testing resistance value is high and the second is low ( compare to the first ). See above photo for example.

2.2

Bad ICs (leak)........both measured resistance value tend to the same value and very high resistance.

2.3

Bad ICs (Short circuit) ....both measured resistance value tend to very low resistance ( almost be 0 ohm )

2.4

Bad ICs ( open circuit) ... the display show " OL" for both measurement.